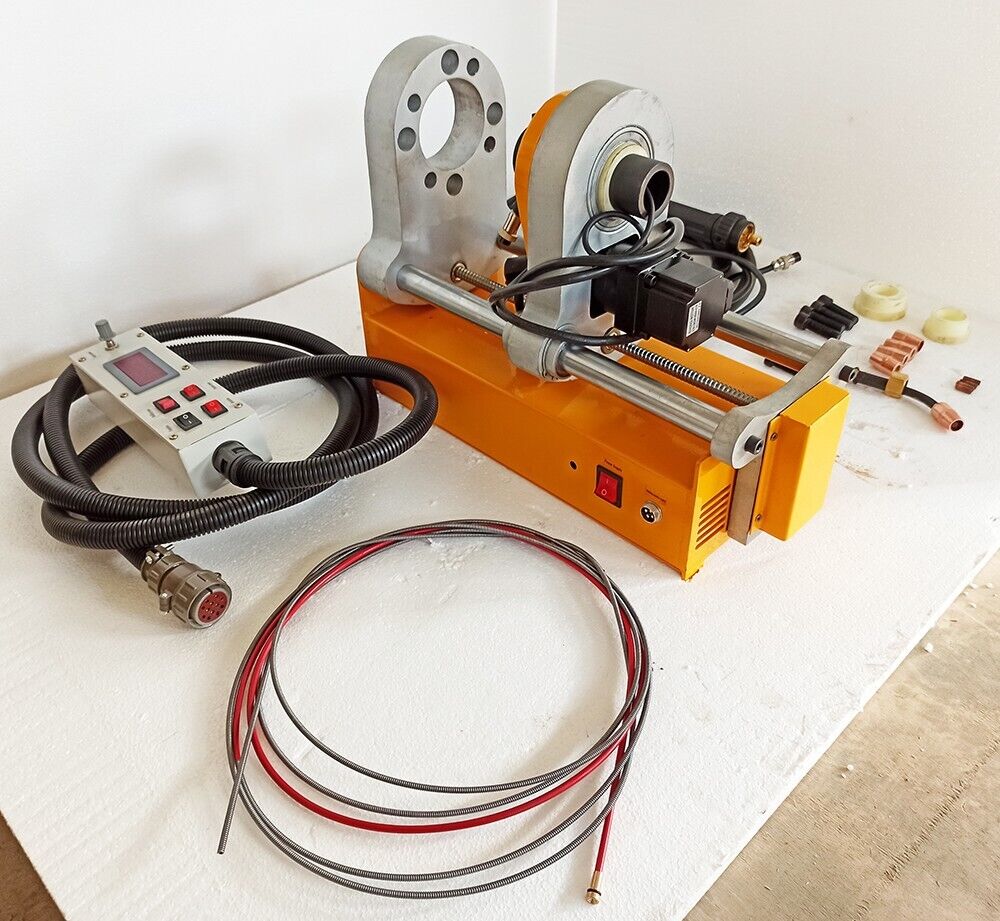

Excavator Auto Rotary

Inner Boring Welder Line Machine Welder Welding

Machinery

Portable Auto Welding Machine Inner Line Bore

Welder for Excavator

Portable Auto Welding Machine Inner Line Bore Welder

for Excavator is designed for site construction, small size, light weight, good

welding quality.

It is easy to carry. It is widely used in the

repair welding of large equipment, construction machinery pin hole, bearing hole

and other round holes.Industrial and mining enterprises, engineering site

maintenance tools.

FEATURES

1.Portable Auto Welding Machine Inner

Line Bore Welder for Excavator

2.Universal torch: Adjust the welding radius

to adapt to different diameters of round hole

3.Mounting support: Connect the

support flange to fix the unit

4.Operation: Turn on the unit, including

welding machine (welding switch to be opened)

5.Rotary switch: Spindle only

moves without rotation when the switch is closed

Inching: pressed: dry run;

released: welder doesn’t work

6.Direction: Direction of axial feed of the

torch

7.Welding switch: turn on: welder works, turn off: welder does not

work

8.High speed: press and then press the inching button, the axial

movement can be faster.

9.Digital display does not represent the actual

speed, only shows fast or slow

10.Speed adjustment: adjust the operating

speed, the greater number represents faster speed

11.Power switch: main power

switch

12.Welder control: connected with the welding machine control

cable

13.Technical Features: Small size and light weight, can be worked with

either MIG welder with Euro standard interface

PARAMETERS

Voltage

110V

Maximum Power:100W

100W

Net Weight

24kg

Spindle Speed

CVT 0–40r/min

Welding range

Φ55-220mm

Axial Travel

0-280mm

Wire Diameter

1.0mm

Ambient Temperature

-10℃~+55℃

Storage

temperature

-25℃~+70℃

Relative humidity

≤85%

Portable Auto Welding Machine Inner Line Bore

Welder for Excavator

1)High strength boring bar,the overall conditioning,

quenching, surface plating, high strength, guaranteed the cutting and the

accuracy

2)Advanced internal and external circular patch welding system, Muti

use in one machie, high efficiency.

3) All accessories and parts design and

manufacture atthe purpose of exquisite, durable and maximum

security.

Line Boring Machine

Hole Drilling+Excavator Auto Rotary Inner Boring Welder

NEW

Hole drilling

machine for engineering machinery is a portable processing equipment developed

for field service of engineering machinery, which is mainly used in processing

of small-scale pipeline inner hole and concentric span hole, and widely applied

in engineering machinery, including excavator, crane, loader, and

hoist.

Note:

Our machines

are constantly improving. The actual received accessories will be slightly

different from the pictures on our web pages. The accessories we send can

guarantee the normal use of boring machine.

Please refer

to the actual product when you receive the accessories. If you have any

questions, you can contact us at any

time.

Attention

This machine is installed by fixed

clamping, and uses different tool rest according to different diameter ranges.

Please confirm the diameter of processing hole before use to select the

appropriate tool rest.

Please read the operation instruction carefully before using the machine,

and check all the items according to packing list to know about operation safety

precautions, machine performance, and usage

specifications.

Features

1.

By

adopting 110V continuous current motor with characteristics of low-speed of

revolution and high torque, the complete machine can realize stationary

machining in superior performance.

2.Feeding and processing can realize

electrodeless speed regulation. Feeding process can be set according to demands,

and processing can automatically stop after reaching the limit

switch.

3.Boring bar adopting high-strength

alloy and structural steel is featured with high hardness, high accuracy, high

tenacity, good abrasion resistance, etc.

4.The boring bar can be disassembled

separately to make installation convenient.

5.The control cabinet is installed

below the main engine to be beneficial to safety operation.

6.

Electric motor controller is equipped with dynamic

delay brake program to avoid vibration in

shutdown.

Main Technical

Parameters

The

maximum processing hole diameter: Ф180mm

The

minimum processing hole diameter: Ф45mm

The

maximum processing travel: 380mm

The

maximum feed depth: 2mm on one side (A3 steel)

Surface roughness:

Ra3.2

Deviation from circular

form≤0.02mm

Gross

weight of equipment: 120KG

Rotate speed: 0-83RPM

Boring bar: 40*1500MM

Power: 1.5KW

1.

Supporting seat A

2. Boring

bar

3.

Supporting seat B

4.

Rack

5. DC

motor

6.

Emergency stop switch

7.

Feeding turning button

8.

Feeding speed governing button

9. Speed

governing button for motor rotation

10.

Alternate switch of motor steering

Equipment

Maintenance

In order to ensure the

use of hole drilling machine for engineering machinery become more convenient

and rapid and every component can work smoothly, regular cleaning and

maintenance have to be done to hole drilling machine.

Slushing oil should be painted to boring

bar and feed screw which are not used very often.

Appropriate grease oil should be added to

the feed box every half a year.

Spindle box and feed box should be stored

by sealing if these parts are not used for a long time.

Appropriate grease oil should be added to

guide post and screw before processing.

Boring bar should be hanged for hoisting

to avoid deformation when it is not processed.

On Nov 29, 2022 at 00:10:26 PST, seller added the following information: